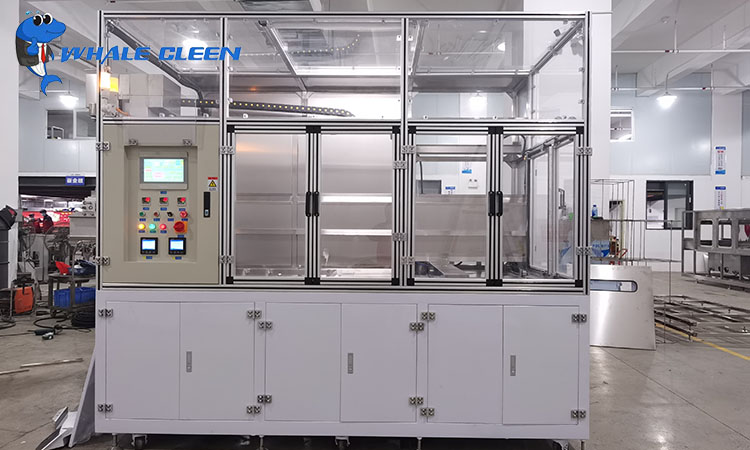

Ultrasonic cleaning machines are innovative tools that leverage high-frequency sound waves to clean objects with precision and efficiency. These machines are integral to multiple industries due to their ability to remove contaminants from complex surfaces and delicate items without causing damage. Identifying the industry classification of ultrasonic cleaning machines involves understanding their technology, applications, and benefits in various sectors.

Ultrasonic cleaning machines can be categorized as industrial equipment or specialized cleaning technology, depending on their application. Below is a detailed breakdown of the industries where these machines are predominantly used:

Sector: Industrial Equipment

Ultrasonic cleaning machines are commonly employed in manufacturing environments for tasks such as:

Sector: Healthcare Equipment

In healthcare, ultrasonic cleaning machines are critical for maintaining hygiene and safety standards. Applications include:

Sector: Electronics Manufacturing

Ultrasonic cleaning is indispensable in electronics due to its ability to clean delicate components without causing damage. Applications include:

Sector: Heavy Industry and Precision Engineering

In these sectors, ultrasonic cleaning machines are used for:

Sector: Consumer Goods Maintenance

Ultrasonic cleaners are popular for maintaining small, intricate items like:

Ultrasonic cleaning machines offer advantages that make them versatile across sectors:

While ultrasonic cleaning machines are widely used, they also face challenges:

The future of ultrasonic cleaning machines lies in innovation and diversification:

Ultrasonic cleaning machines are a vital part of multiple industries, from healthcare to aerospace. They are classified as industrial equipment due to their technological design and functionality, while their applications extend to precision cleaning in various domains. Understanding their classification and industry relevance helps highlight their critical role in enhancing productivity, maintaining quality, and ensuring safety standards.

By continually evolving to meet the demands of modern industries, ultrasonic cleaning machines will remain a cornerstone of advanced cleaning technologies, bridging the gap between efficiency and precision.

Related Issues not found

Please contact @269986972 to initialize the comment