-

Which frequency of ultrasonic cleaner is used more? Can you wash the key cap?

Which frequency of ultrasonic cleaner is used more? Can you wash the key cap?

The frequency range in which an ultrasonic cleaning machine is used depends on the shape and material of the cleaning. The cavitation effect determines the cleaning effect, and the ultrasonic frequency directly affects the cavitation effect. In general, t

-

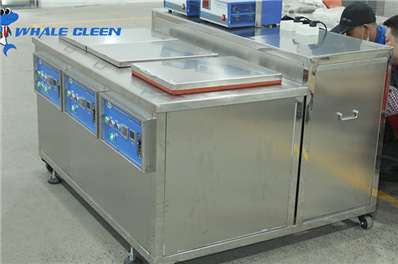

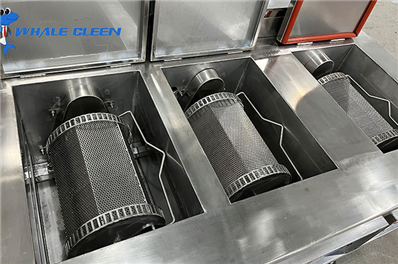

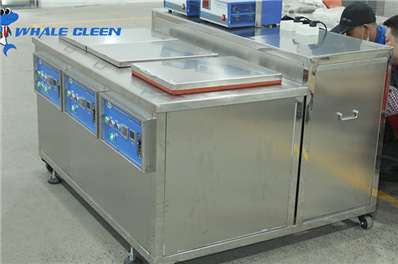

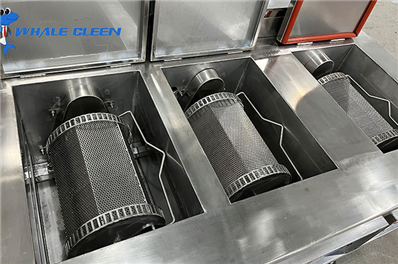

Precautions for using a multi-groove ultrasound cleaning machine

Precautions for using a multi-groove ultrasound cleaning machine

Ultrasonic cleaning originated in the 1960s. Since the advent of ultrasonic technology, scientists have discovered that ultrasonic in a certain frequency range acts in liquid media and can achieve the role of cleaning. As we all know, the sound people hea

-

Optimal Frequency Bandwidth Setting for Ultrasonic Cleaning Machines

Optimal Frequency Bandwidth Setting for Ultrasonic Cleaning Machines

Ultrasonic cleaning machines are widely used in industrial settings for their ability to efficiently and effectively clean a variety of surfaces. One crucial aspect of ultrasonic cleaning machines is the setting of the frequency bandwidth, which directly

-

What is a Nano Ultrasonic Cleaning Machine? An In-depth Overview

What is a Nano Ultrasonic Cleaning Machine? An In-depth Overview

1. Introduction Ultrasonic cleaning technology has been widely used in various industries for cleaning delicate and complex parts. From jewelry and precision……

-

What Is an Ultrasonic Cleaner Transducer: Principles and Applications

What Is an Ultrasonic Cleaner Transducer: Principles and Applications

The ultrasonic cleaner is a widely used cleaning device in industries ranging from healthcare to precision engineering. At the heart of this technology lies the ultrasonic transducer, a critical component responsible for converting electrical energy into

-

Choosing the Right Frequency for Ultrasonic Cleaning Machines: A Professional Overview

Choosing the Right Frequency for Ultrasonic Cleaning Machines: A Professional Overview

Ultrasonic cleaning has become a standard process in various industries due to its efficiency in removing contaminants from delicate and complex surfaces. Whether it's cleaning precision electronics, medical devices, automotive parts, or industrial eq

-

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

In the quest for efficiency, precision, and sustainability, ultrasonic cleaning machines have emerged as a game-changer in the cleaning industry. Leveraging the power of sound waves to achieve unparalleled cleanliness, these machines have carved out a lea

-

The New Trend in the Cleaning Industry: Ultrasonic Cleaning Technology

The New Trend in the Cleaning Industry: Ultrasonic Cleaning Technology

In recent years, ultrasonic cleaning has emerged as a cutting-edge solution for various industries, transforming the way cleaning is done, from industrial machinery to delicate instruments. The ultrasonic cleaning machine, utilizing high-frequency sound w

-

The Pinnacle of Clean Technology: A Comprehensive Guide to Ultrasonic Cleaners

The Pinnacle of Clean Technology: A Comprehensive Guide to Ultrasonic Cleaners

In the modern era of clean technology, ultrasonic cleaners stand out as a premier solution for achieving high precision and efficiency in cleaning. Unlike traditional cleaning methods that rely on manual scrubbing or harsh chemicals, ultrasonic cleaning u

-

Innovative Technologies and Future Trends in Ultrasonic Cleaning Equipment

Innovative Technologies and Future Trends in Ultrasonic Cleaning Equipment

Ultrasonic cleaning technology has revolutionized the way industries approach the cleaning of delicate and complex components. By using high-frequency sound waves to create cavitation bubbles in a cleaning solution, ultrasonic cleaners can remove contamin

-

The Effectiveness of Ultrasonic Vibration Plates in Cleaning Aerospace Components

The Effectiveness of Ultrasonic Vibration Plates in Cleaning Aerospace Components

The aerospace industry demands the highest standards of cleanliness for its components. Any contamination, even at microscopic levels, can compromise the performance and safety of aerospace equipment. Traditional cleaning methods often fall short in meeti

-

Ultrasonic Cleaning Equipment: The Optimal Choice for Enhancing Metal Surface Cleanliness

Ultrasonic Cleaning Equipment: The Optimal Choice for Enhancing Metal Surface Cleanliness

Maintaining the cleanliness of metal surfaces is a critical aspect in various industrial processes. Metal parts often require stringent cleaning standards to ensure proper functionality and longevity, particularly in industries such as aerospace, automoti

Which frequency of ultrasonic cleaner is used more? Can you wash the key cap?

Which frequency of ultrasonic cleaner is used more? Can you wash the key cap?

Precautions for using a multi-groove ultrasound cleaning machine

Precautions for using a multi-groove ultrasound cleaning machine

Optimal Frequency Bandwidth Setting for Ultrasonic Cleaning Machines

Optimal Frequency Bandwidth Setting for Ultrasonic Cleaning Machines

What is a Nano Ultrasonic Cleaning Machine? An In-depth Overview

What is a Nano Ultrasonic Cleaning Machine? An In-depth Overview

What Is an Ultrasonic Cleaner Transducer: Principles and Applications

What Is an Ultrasonic Cleaner Transducer: Principles and Applications

Choosing the Right Frequency for Ultrasonic Cleaning Machines: A Professional Overview

Choosing the Right Frequency for Ultrasonic Cleaning Machines: A Professional Overview

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

Innovation in Cleaning: The Industry Leadership of Ultrasonic Cleaning Machines

The New Trend in the Cleaning Industry: Ultrasonic Cleaning Technology

The New Trend in the Cleaning Industry: Ultrasonic Cleaning Technology

The Pinnacle of Clean Technology: A Comprehensive Guide to Ultrasonic Cleaners

The Pinnacle of Clean Technology: A Comprehensive Guide to Ultrasonic Cleaners

Innovative Technologies and Future Trends in Ultrasonic Cleaning Equipment

Innovative Technologies and Future Trends in Ultrasonic Cleaning Equipment

The Effectiveness of Ultrasonic Vibration Plates in Cleaning Aerospace Components

The Effectiveness of Ultrasonic Vibration Plates in Cleaning Aerospace Components

Ultrasonic Cleaning Equipment: The Optimal Choice for Enhancing Metal Surface Cleanliness

Ultrasonic Cleaning Equipment: The Optimal Choice for Enhancing Metal Surface Cleanliness