Ultrasonic cleaning has revolutionized the way industries handle the cleaning of glassware. From laboratory settings to industrial applications, ultrasonic cleaners offer unmatched precision and efficiency. This article delves into the industry standards governing the use of ultrasonic cleaning equipment for glassware, highlighting the protocols, benefits, and technological advancements that ensure optimal cleaning.

Glassware, commonly used in laboratories, medical facilities, and various industrial applications, requires meticulous cleaning to maintain its integrity and functionality. Traditional cleaning methods often fall short in removing microscopic contaminants, residues, and particulates. Ultrasonic cleaning technology, leveraging high-frequency sound waves, creates cavitation bubbles in a cleaning solution, which implode to dislodge and remove contaminants from glass surfaces.

The use of ultrasonic cleaning equipment in glassware cleaning is guided by stringent industry standards to ensure safety, efficacy, and reliability. Key standards include:

ASTM G131-96 (2016) Standard Practice for Cleaning of Materials by Ultrasonic Techniques:This standard outlines the procedures for ultrasonic cleaning, including the preparation of cleaning solutions, equipment setup, and cleaning parameters such as frequency, temperature, and duration. It emphasizes the importance of using appropriate cleaning agents compatible with glassware.

ISO 19603:2018 Cleanliness of Optical Glass and Ophthalmic Lenses:While primarily focused on optical glass, this standard provides valuable insights into the ultrasonic cleaning processes for glassware, detailing the acceptable levels of cleanliness and the methods for verifying the removal of contaminants.

USP <1072> Disinfectants and Antiseptics:Although not specific to ultrasonic cleaning, this standard highlights the importance of using effective disinfectants and antiseptics in conjunction with ultrasonic cleaning to ensure thorough decontamination of glassware used in medical and laboratory settings.

Adhering to established protocols is crucial for achieving consistent and effective cleaning results. The general steps involved in ultrasonic cleaning of glassware are as follows:

Pre-Cleaning:Remove gross contaminants by rinsing or wiping the glassware with water or a mild detergent solution.

Preparation of Cleaning Solution:Prepare a cleaning solution based on the type of contaminants and the glassware material. Common solutions include mild alkaline detergents, enzymatic cleaners, or specialized glass cleaning agents.

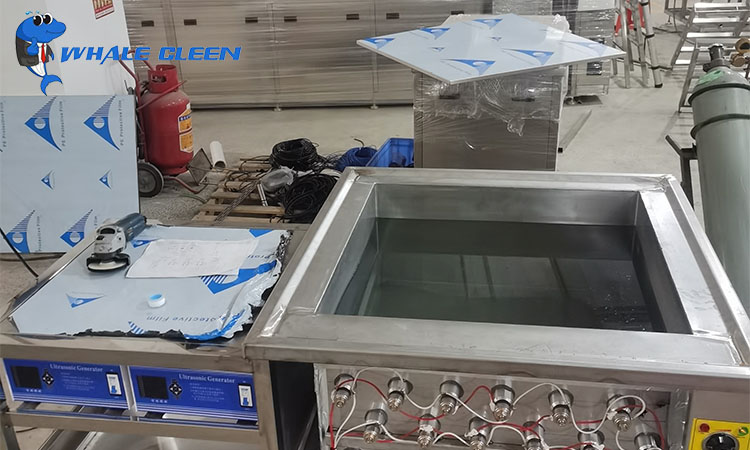

Ultrasonic Cleaning Process:

Rinsing and Drying:After cleaning, thoroughly rinse the glassware with deionized water to remove any residual cleaning agents. Dry the glassware using a lint-free cloth or an air dryer to prevent water spots.

Ultrasonic cleaning offers several advantages over traditional cleaning methods:

Recent advancements in ultrasonic cleaning technology have further enhanced its effectiveness in glassware cleaning:

The adoption of ultrasonic cleaning equipment in glassware cleaning is governed by well-defined industry standards and protocols, ensuring safety, efficacy, and reliability. By following these guidelines and leveraging the benefits of ultrasonic technology, industries can achieve superior cleaning results, maintain the integrity of their glassware, and enhance overall operational efficiency. As technology continues to evolve, ultrasonic cleaning will undoubtedly remain a cornerstone in the maintenance of glassware across various sectors.

Related Issues not found

Please contact @269986972 to initialize the comment