Metallic batteries are critical components of many modern technologies, including electric vehicles, consumer electronics, and renewable energy storage systems. The performance and lifespan of these batteries depend significantly on the cleanliness of their electrode plates. Over time, electrode plates can accumulate dirt, dust, and electrolyte residue, which can compromise their conductivity and impair their ability to charge and discharge efficiently. Therefore, it is essential to clean the electrode plates regularly to maintain the battery's optimal performance.

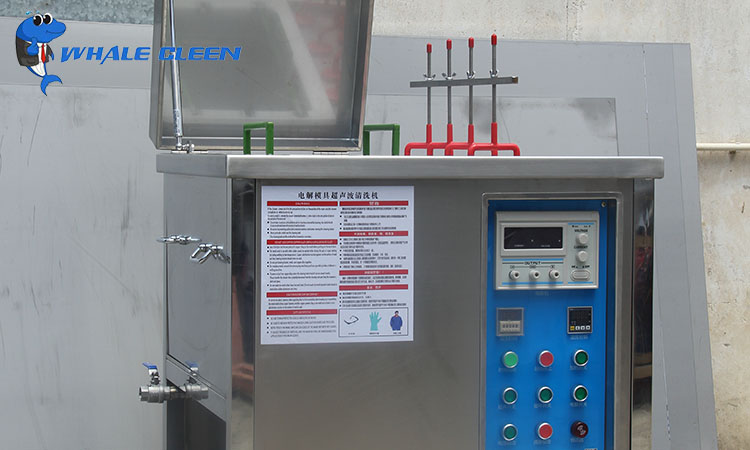

Ultrasonic cleaning machines are a popular solution for cleaning metallic battery electrode plates. These machines use high-frequency sound waves to create microscopic bubbles in a cleaning solution, which implode upon contact with the surface to be cleaned. This implosion generates a powerful scrubbing action that dislodges dirt, dust, and other contaminants from the electrode plates' surface. Ultrasonic cleaning is a non-abrasive, non-destructive process that can clean even the most delicate and complex-shaped electrode plates without damaging them.

The ultrasonic cleaning process is straightforward. First, the electrode plates are immersed in a cleaning solution that is specially formulated to remove the type of contaminants present on the plates. The cleaning solution should be chosen carefully to avoid damaging the electrode plates or the battery's internal components. Once the plates are submerged, the ultrasonic cleaning machine is turned on, and the cleaning solution is agitated by high-frequency sound waves. The cleaning process typically takes several minutes, depending on the size and complexity of the electrode plates.

After the cleaning process is complete, the electrode plates are rinsed thoroughly with deionized water to remove any remaining cleaning solution and contaminants. Any residual moisture is removed using a hot air dryer or a clean, lint-free cloth. Once the electrode plates are completely dry, they can be reassembled into the battery, and the battery can be put back into service.

The benefits of using ultrasonic cleaning machines to clean metallic battery electrode plates are numerous. First, ultrasonic cleaning is a highly effective cleaning method that can remove even stubborn contaminants that other cleaning methods cannot. Second, ultrasonic cleaning is a non-abrasive, non-destructive process that does not damage the electrode plates or the battery's internal components. Third, ultrasonic cleaning is fast, efficient, and can be easily automated, making it a cost-effective cleaning solution for high-volume production environments.

In conclusion, the cleanliness of metallic battery electrode plates is critical to the performance and lifespan of the battery. Ultrasonic cleaning machines are an effective, non-destructive, and cost-effective solution for cleaning electrode plates and improving battery efficiency and lifespan. By regularly cleaning battery electrode plates with an ultrasonic cleaning machine, battery manufacturers and users can ensure that their batteries perform optimally and have a long lifespan.

Related Issues not found

Please contact @269986972 to initialize the comment