Knowledge | 2023-10-31

Ultrasonic Cleaning Technology for Ensuring Optimal Performance of Electrical Metal Equipment

Return

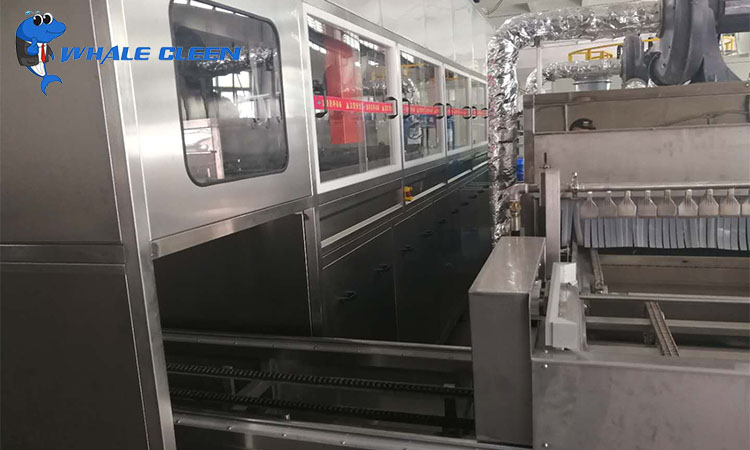

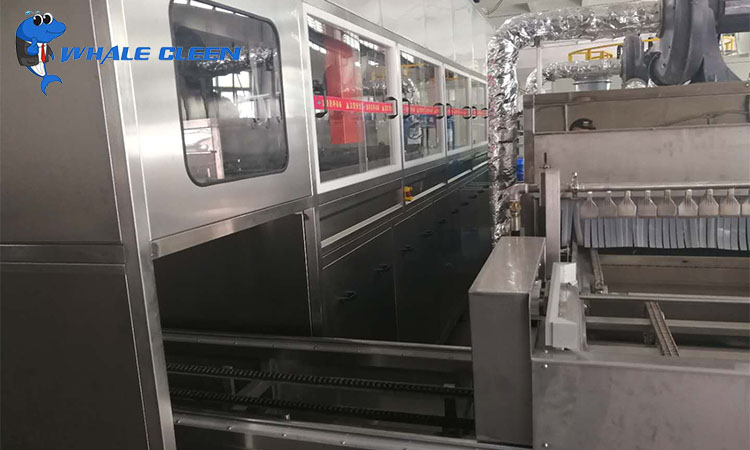

Cleaning electrical metal equipment is crucial for maintaining their efficiency and prolonging their lifespan. Ultrasonic cleaning technology plays a vital role in this process. This article will delve into how ultrasonic cleaning machines ensure the efficient operation of electrical metal equipment, providing a professional perspective on the matter.

I. Cleaning Requirements for Electrical Equipment:

Electrical equipment, including generators, transformers, and switchgear components, are critical to power systems. However, prolonged operation in high-temperature and high-pressure environments can lead to the accumulation of dirt, deposits, and corrosive substances on their surfaces. Regular cleaning and maintenance are essential to ensure their optimal performance.

II. Principles of Ultrasonic Cleaning Technology:

Ultrasonic cleaning machines operate on the principle of generating high-frequency ultrasonic waves to create microscopic bubbles and eddy currents, which effectively clean the surface of objects. The process can be summarized as follows:

-

The ultrasonic generator produces high-frequency sound waves typically ranging from 20 kHz to 40 kHz.

-

The sound waves propagate through a liquid, creating microscopic bubbles. These bubbles expand and contract under the influence of the sound waves, generating high-intensity pressure waves.

-

The pressure waves exert force on the surface of the object, effectively dislodging dirt, deposits, and corrosion layers.

-

Eddy currents are formed, aiding in the removal of dirt from the object's surface.

This mechanism makes ultrasonic cleaning technology highly suitable for cleaning electrical metal equipment, as it can penetrate and clean even intricate components uniformly without causing mechanical damage.

III. Applications of Ultrasonic Cleaning Machines in Electrical Equipment Maintenance:

-

Cleaning Generators and Transformers: Generators and transformers are vital components of power systems. Their insulation components and heat dissipation surfaces are prone to accumulating dust and oil residues. Ultrasonic cleaning machines can thoroughly clean these components, ensuring efficient heat dissipation and insulation performance.

-

Clearing Switchgear Components: Switchgear components, such as circuit breakers and disconnectors, may become contaminated by arc-generated pollutants during operation. Ultrasonic cleaning machines effectively remove residue from electric arcs, ensuring the stable operation of switchgear.

-

Corrosion Prevention: Electrical equipment is often exposed to high temperatures, pressures, and humidity, making them susceptible to corrosion. Ultrasonic cleaning machines can remove corrosion products from the metal surfaces, thereby extending the equipment's lifespan.

IV. Advantages of Ultrasonic Cleaning Machines:

Ultrasonic cleaning machines offer several advantages in electrical equipment maintenance:

-

Efficient Cleaning: Ultrasonic cleaning machines can reach even the tiniest components, effectively removing hard-to-reach dirt and deposits, thus enhancing cleaning efficiency.

-

Environmentally Friendly: Compared to traditional chemical cleaning methods, ultrasonic cleaning eliminates the need for harmful solvents, reducing environmental pollution.

-

Energy and Resource Conservation: The cleaning process does not require high temperatures or pressures, reducing energy consumption and resource wastage.

-

Equipment Protection: The cleaning process with ultrasonic waves is gentle and does not cause mechanical damage to electrical equipment.

-

Extended Equipment Lifespan: Regular use of ultrasonic cleaning machines can prolong the lifespan of electrical equipment, reducing maintenance and replacement costs.

Conclusion:

Ultrasonic cleaning technology plays a pivotal role in ensuring the efficient operation of electrical metal equipment. Through high-frequency sound wave vibrations, ultrasonic cleaning machines can thoroughly clean intricate components, guaranteeing optimal performance. Furthermore, the technology's environmentally friendly, efficient, and resource-saving attributes make it an indispensable solution for electrical equipment maintenance.